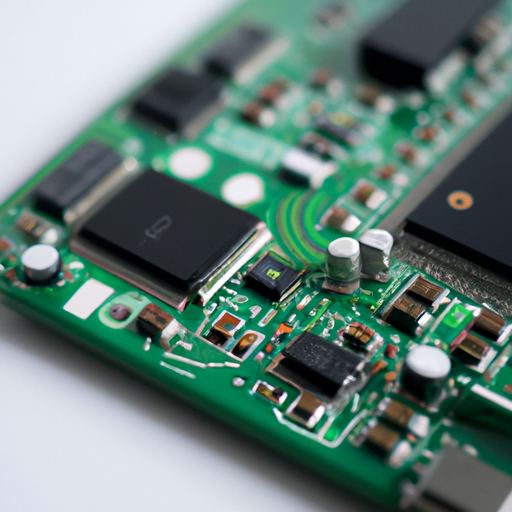

The production process of computing amplifier assessment boards is a crucial step in the manufacturing of electronic devices. These boards are essential components in computers, amplifiers, and other electronic devices, as they help to amplify and process signals for optimal performance. In this article, we will explore the mainstream production process of computing amplifier assessment boards, from design to testing.

The first step in the production process of computing amplifier assessment boards is the design phase. This phase involves creating a detailed schematic of the board, including the layout of components, connections, and signal paths. Design engineers use specialized software to create these schematics, ensuring that all components are placed correctly and that the board will function as intended.

Once the schematic is complete, the design engineers create a physical layout of the board using computer-aided design (CAD) software. This layout includes the placement of components on the board, as well as the routing of signal paths between components. Design engineers must carefully consider factors such as signal integrity, power distribution, and thermal management during this phase to ensure the board will function properly.

Prototype Development:

After the design phase is complete, the next step in the production process is prototype development. Prototype boards are manufactured using the design schematics and layouts created in the previous phase. These boards are typically produced in small quantities for testing and validation purposes.

During prototype development, manufacturers use specialized equipment such as pick-and-place machines and reflow ovens to assemble the components onto the board. Once the components are soldered in place, the board is tested for functionality and performance. Design engineers may make adjustments to the design based on the results of these tests, refining the board for optimal performance.

Mass Production:

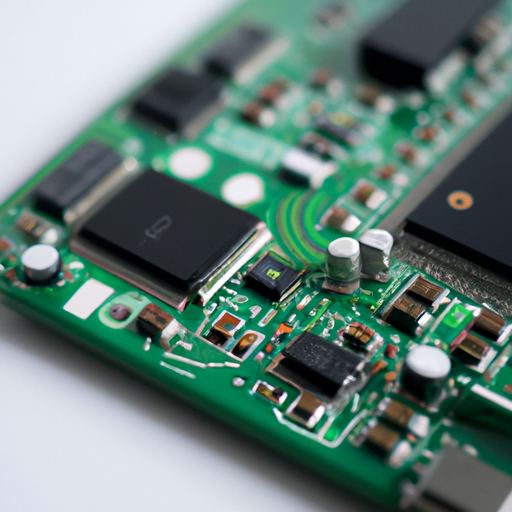

Once the prototype boards have been validated and approved, the production process moves into mass production. During this phase, manufacturers produce large quantities of computing amplifier assessment boards using automated assembly processes. These processes are designed to maximize efficiency and consistency in the production of the boards.

Manufacturers use high-speed pick-and-place machines to accurately place components onto the boards, followed by reflow ovens to solder the components in place. Automated optical inspection (AOI) systems are used to check for defects in the solder joints and components, ensuring the quality of the boards.

Testing and Quality Control:

After the boards have been assembled, they undergo rigorous testing and quality control procedures to ensure they meet the required specifications. Testing may include functional testing to verify that the board operates as intended, as well as performance testing to measure signal quality and amplification capabilities.

In addition to testing, manufacturers also implement quality control measures throughout the production process to ensure consistency and reliability in the boards. This may include inspections of components, solder joints, and overall board quality to identify and address any issues that may arise.

Packaging and Shipping:

Once the boards have passed testing and quality control, they are packaged and prepared for shipping to customers. Packaging may include anti-static bags or trays to protect the boards during transit, as well as labeling and documentation for identification and tracking purposes.

Manufacturers work closely with logistics partners to ensure the boards are shipped safely and efficiently to customers around the world. This may involve coordinating with shipping carriers, customs officials, and other parties to ensure timely delivery of the boards.

Conclusion:

The production process of computing amplifier assessment boards is a complex and intricate process that requires careful planning, design, and execution. From the initial design phase to prototype development, mass production, testing, and shipping, manufacturers must adhere to strict quality control measures to ensure the boards meet the required specifications and perform as intended.

By following a systematic approach to production, manufacturers can produce high-quality computing amplifier assessment boards that meet the demands of the electronics industry. With advancements in technology and manufacturing processes, the production of these boards continues to evolve, enabling manufacturers to produce boards that are more efficient, reliable, and cost-effective for a wide range of applications.

The production process of computing amplifier assessment boards is a crucial step in the manufacturing of electronic devices. These boards are essential components in computers, amplifiers, and other electronic devices, as they help to amplify and process signals for optimal performance. In this article, we will explore the mainstream production process of computing amplifier assessment boards, from design to testing.

The first step in the production process of computing amplifier assessment boards is the design phase. This phase involves creating a detailed schematic of the board, including the layout of components, connections, and signal paths. Design engineers use specialized software to create these schematics, ensuring that all components are placed correctly and that the board will function as intended.

Once the schematic is complete, the design engineers create a physical layout of the board using computer-aided design (CAD) software. This layout includes the placement of components on the board, as well as the routing of signal paths between components. Design engineers must carefully consider factors such as signal integrity, power distribution, and thermal management during this phase to ensure the board will function properly.

Prototype Development:

After the design phase is complete, the next step in the production process is prototype development. Prototype boards are manufactured using the design schematics and layouts created in the previous phase. These boards are typically produced in small quantities for testing and validation purposes.

During prototype development, manufacturers use specialized equipment such as pick-and-place machines and reflow ovens to assemble the components onto the board. Once the components are soldered in place, the board is tested for functionality and performance. Design engineers may make adjustments to the design based on the results of these tests, refining the board for optimal performance.

Mass Production:

Once the prototype boards have been validated and approved, the production process moves into mass production. During this phase, manufacturers produce large quantities of computing amplifier assessment boards using automated assembly processes. These processes are designed to maximize efficiency and consistency in the production of the boards.

Manufacturers use high-speed pick-and-place machines to accurately place components onto the boards, followed by reflow ovens to solder the components in place. Automated optical inspection (AOI) systems are used to check for defects in the solder joints and components, ensuring the quality of the boards.

Testing and Quality Control:

After the boards have been assembled, they undergo rigorous testing and quality control procedures to ensure they meet the required specifications. Testing may include functional testing to verify that the board operates as intended, as well as performance testing to measure signal quality and amplification capabilities.

In addition to testing, manufacturers also implement quality control measures throughout the production process to ensure consistency and reliability in the boards. This may include inspections of components, solder joints, and overall board quality to identify and address any issues that may arise.

Packaging and Shipping:

Once the boards have passed testing and quality control, they are packaged and prepared for shipping to customers. Packaging may include anti-static bags or trays to protect the boards during transit, as well as labeling and documentation for identification and tracking purposes.

Manufacturers work closely with logistics partners to ensure the boards are shipped safely and efficiently to customers around the world. This may involve coordinating with shipping carriers, customs officials, and other parties to ensure timely delivery of the boards.

Conclusion:

The production process of computing amplifier assessment boards is a complex and intricate process that requires careful planning, design, and execution. From the initial design phase to prototype development, mass production, testing, and shipping, manufacturers must adhere to strict quality control measures to ensure the boards meet the required specifications and perform as intended.

By following a systematic approach to production, manufacturers can produce high-quality computing amplifier assessment boards that meet the demands of the electronics industry. With advancements in technology and manufacturing processes, the production of these boards continues to evolve, enabling manufacturers to produce boards that are more efficient, reliable, and cost-effective for a wide range of applications.